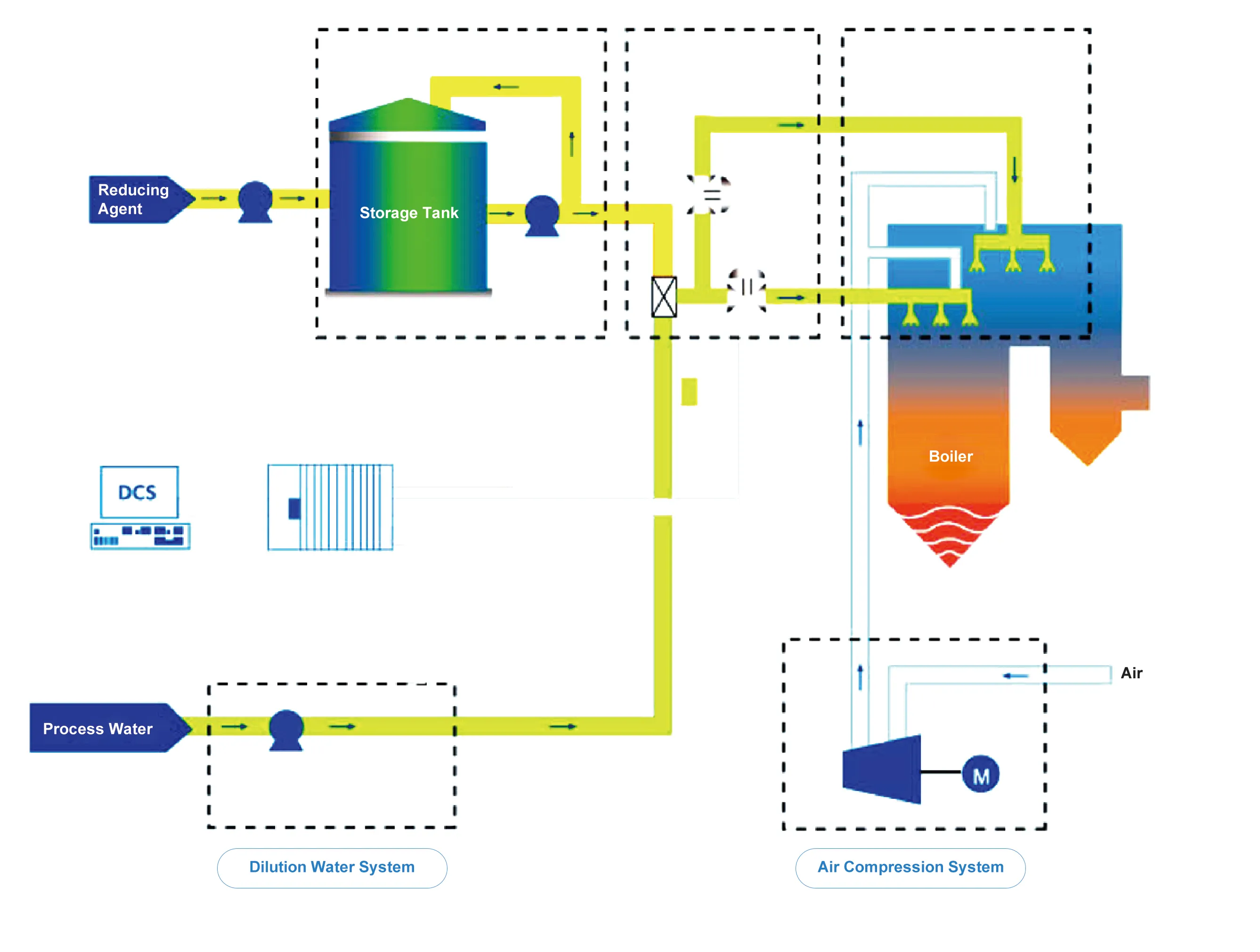

SNCR denitrification process

Operational requirement

Reductant:Liquid ammonia, ammonia water, urea aqueous solution, etc

Catalyst:None

Temperature:800 to 1000 ° C

Reduction rate:40%~65%

Ammonia escape dfafe concentration:≤3ppm

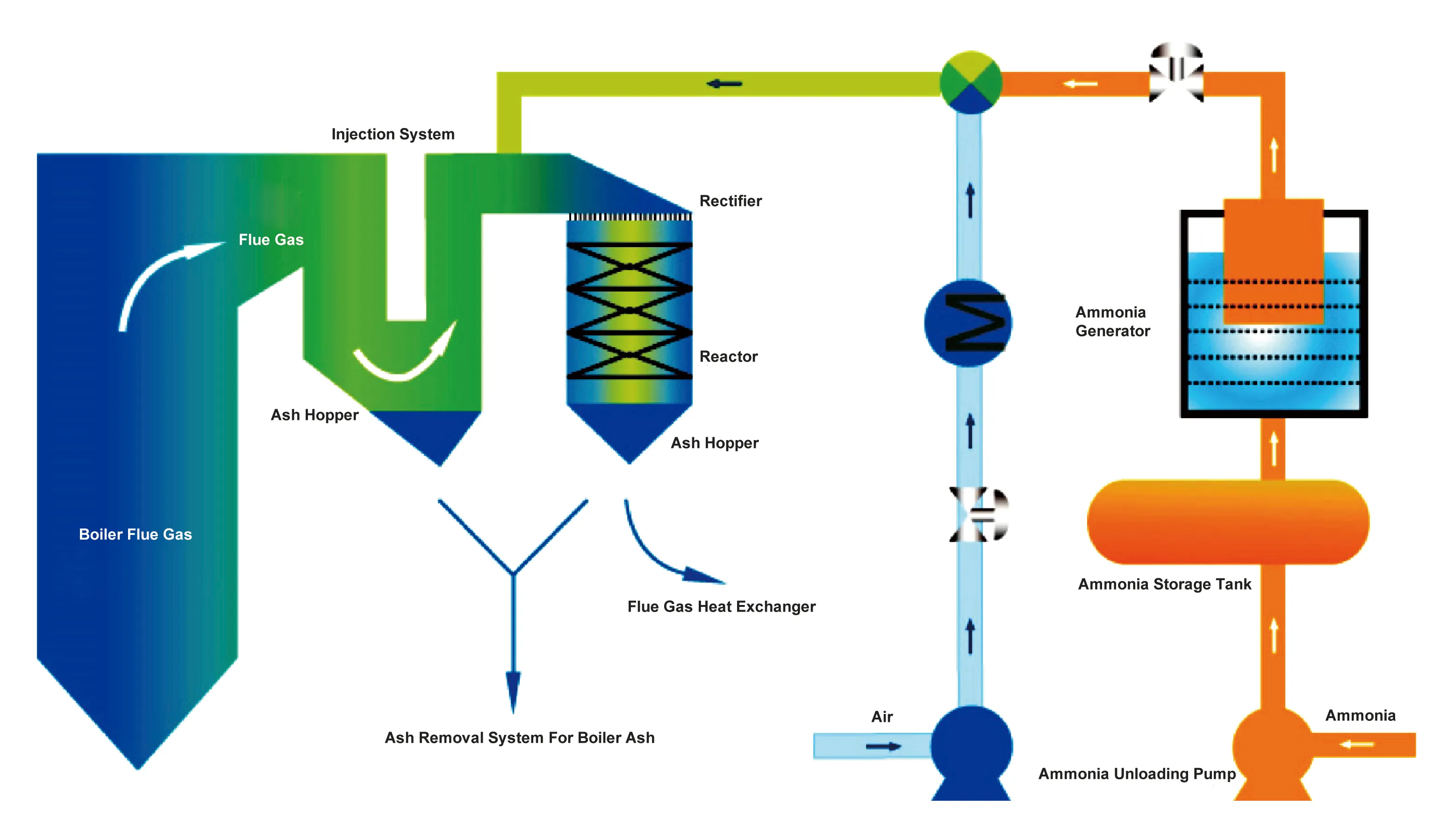

SNCR denitrification process

Operational requirement

Reductant:ammonia, urea aqueous solution, etc

Catalyst:vanadium or titanium based catalyst

Temperature:300-420℃

Reduction rate:70%~95%

Ammonia escape dfafe concentration:≤3ppm

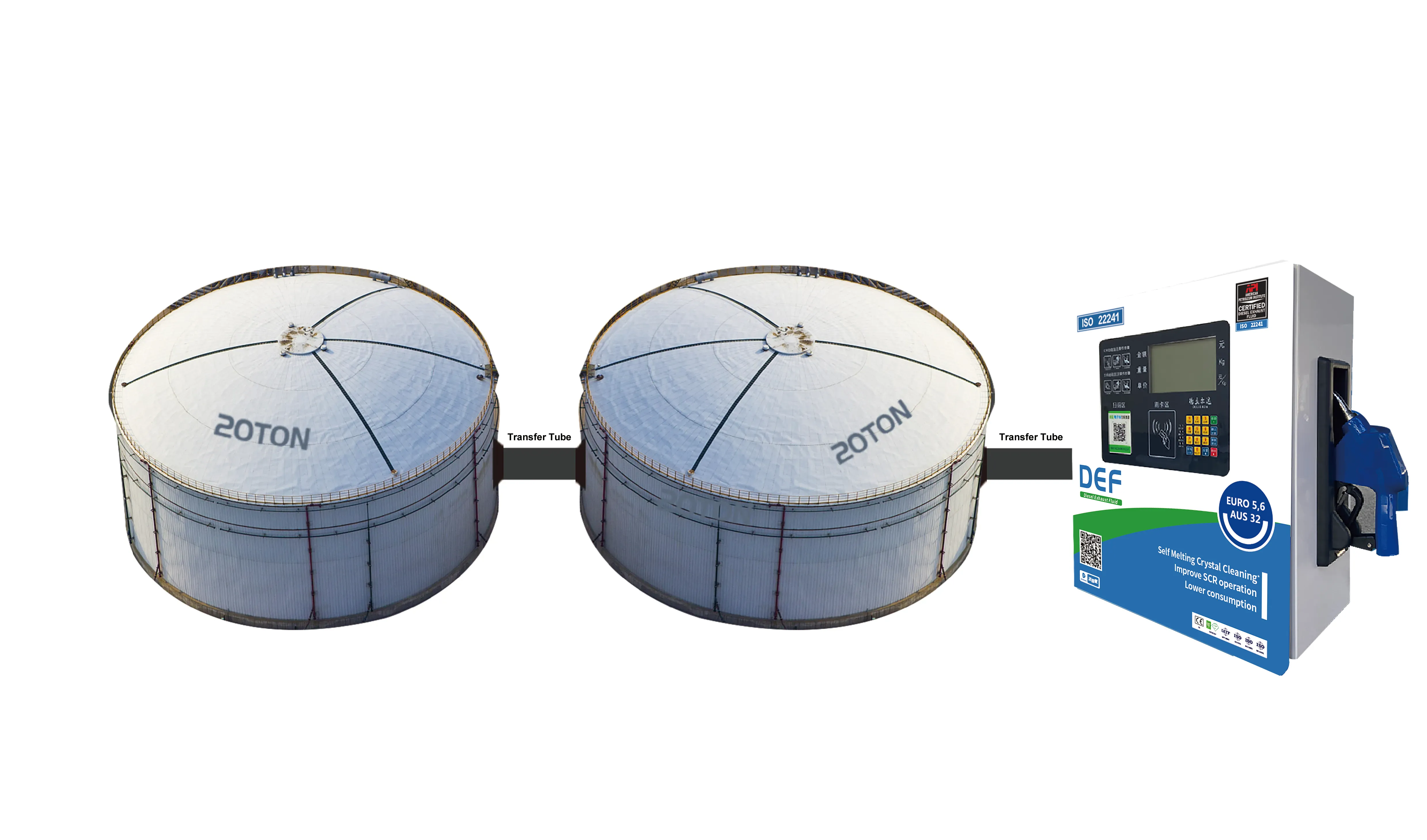

ADVANTAGES OF ON-SITE SUPPLY UNITS

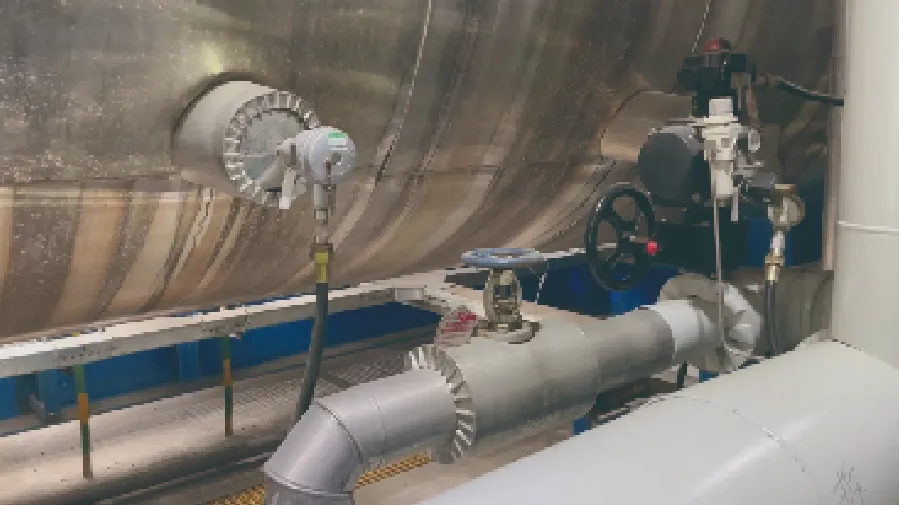

SMC self-melting crystal cleaning technology

Large tonnage equipment

Suitable for very long pipelines

100L/min High flow rate

1

High storage security

The solution is non-toxic and has no storage pressure

The solution is non-toxic and has no storage pressure

2

Solution quality stability

The supply is stable and guaranteed

The supply is stable and guaranteed

3

Large tonnage equipment covers a small area

High transmission velocity

High transmission velocity

BETTER FUTURE supplies Nanjing and Anhui power companies with 20% concentration standard urea aqueous solution suitable for SCR denitration device.

Nanjing electric power company

External device

Internal hydrolyzing equipment

Ammonia gas supply tube device

Ammonia gas supply tube device

Anhui power company

External device

Internal hydrolyzing equipment

Urea solution storage device

Assistant

Hello! What do you need help with?